Subcontracting & Welding Services

Reliable Services for Industrial Applications

At Finmatec, you get comprehensive subcontracting and welding services specifically tailored to meet your needs in the process and storage industries. We focus on critical maintenance and manufacturing tasks, making sure your sludge silos and other industrial equipment maintain peak performance and long-lasting durability.

- Pickling: Chemical cleaning for stainless steel components, removing welding discoloration and ensuring corrosion resistance.

- Welding: Precision welding of steel and stainless steel structures, tailored to industrial standards for durability and safety.

- Glassblasting: Surface treatment for enhanced cleanliness and finish, ideal for silo maintenance and production environments.

With decades of experience and a commitment to quality, Finmatec is your reliable partner for maintaining hygienic, efficient, and long-lasting silo systems. Let us help you optimize your production with our specialized services.

Efficient and Cost-Effective

High-Quality Surface Finish

Customized Solutions Upon Request

Reliable and Proven Techniques

Safe and Environmentally Conscious

Flexible Scheduling

Industrial Pickling Services for Stainless Steel Perfection

At Finmatec, you get professional pickling services tailored to your needs as part of our subcontracting capabilities. Pickling is a critical finishing step for your stainless steel components and systems. With our controlled chemical treatment, you can ensure that welding discoloration, oxides, heat tint, and other surface contaminants from fabrication and thermal processing are effectively removed.

By choosing our pickling services, you restore the passive protective layer on your stainless steel surfaces. This guarantees long-term corrosion resistance, hygienic finishes, and a visually uniform appearance – crucial for your operations in food production, pharmaceuticals, or any process industry where cleanliness and material integrity are essential.

Our pickling process adapts to your specific applications, from small parts to large welded structures. Whether you need pickling for tanks, platforms, piping, or structural frames, we treat every surface thoroughly and consistently. You can choose standalone pickling jobs or include it as part of a complete subcontracted manufacturing package from our workshop.

We make sure to align with your production requirements, offering short lead times, high capacity, and consistent quality. With our experienced team and strict process control, you can trust Finmatec to keep your surfaces clean, safe, and ready for production – every time.

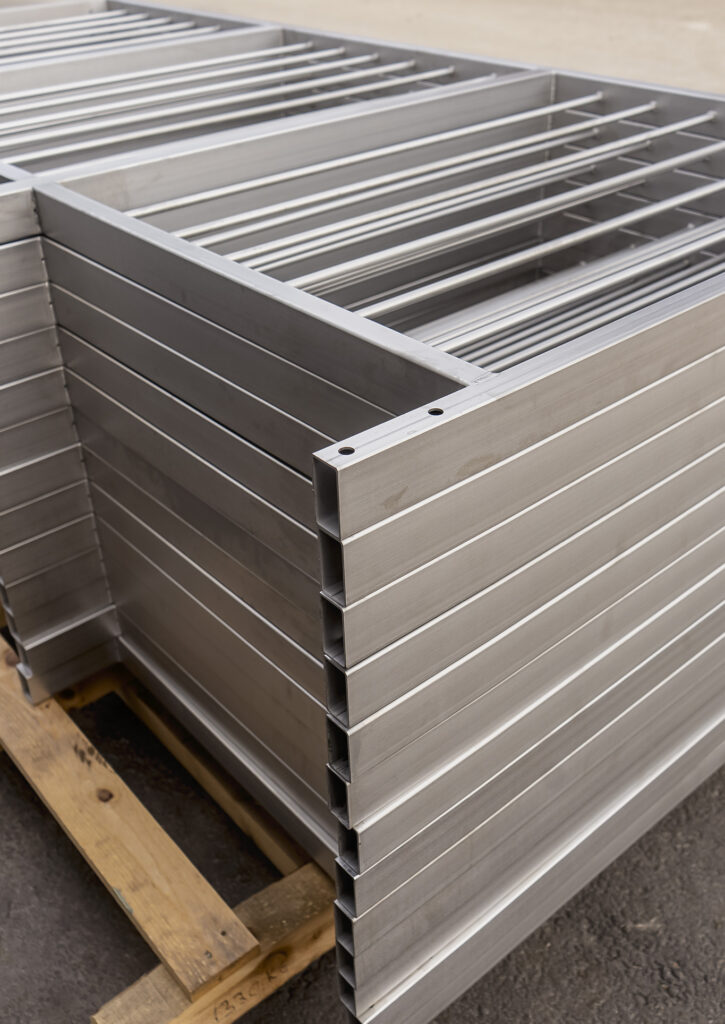

High-Quality Welding for Industrial Applications

The silo system can be constructed for both fresh and frozen products. Furthermore, the usage of silos for feeding the production line At Finmatec, welding is more than just a manufacturing step for you – it’s a crucial part of ensuring your equipment is robust, hygienic, and built to last. You can count on our decades of experience and in-house welding specialists to deliver precision and strength in every joint we create.

You deserve welding solutions that meet the highest standards. That’s why we work with stainless steel (AISI 304 / 316) and other materials suited for demanding environments where hygiene, corrosion resistance, and structural integrity are essential. Whether you’re in food production, wet pet food processing, or industrial system manufacturing, we make sure our welded components meet both regulatory requirements and your specific production needs.

If you need welded frames, tanks, platforms, or integrated process systems, we’ve got you covered. We approach every project with your requirements in mind, working closely with you to ensure the highest quality. You can rely on Finmatec to deliver precise, reliable, and durable welding – because we know that a perfect weld is what keeps your production running smoothly.

The most efficient discharge on the market

“Years of experience and dedicated work is the key to the reliability and efficiency of our discharge sludge solutions.”

Anders Asplund CEO Finmatec Oy Ab

Professional Glassblasting for Industrial Applications

When you need a reliable and hygienic surface finish for your equipment, glassblasting is the solution you can trust. At Finmatec, we offer professional glassblasting services designed to meet the highest standards of cleanliness and durability, especially for applications in the food and process industries.

With our glassblasting process, you achieve a smooth, matte finish that not only improves the appearance of your stainless steel components but also enhances their resistance to corrosion. This makes it an ideal choice for your sludge silos, storage silos, and other industrial equipment exposed to demanding conditions.

You can count on us to tailor the glassblasting process to your specific requirements, whether it’s for newly manufactured parts or maintenance of existing equipment. Our skilled team ensures that every surface is treated with precision, providing a uniform, high-quality result.

Choose Finmatec for your glassblasting needs – because your equipment deserves a professional, long-lasting finish. Let us help you keep your production running efficiently and hygienically.

Want to Get in Touch?

We are happy to answer any and every question you might have regarding our products!

MATS STRANDVALL

Sales Director

Sales

mats.strandvall@finmatec.fi

+358 40 086 2694

Unsure who to contact?

Give us your contact information and we will contact you shortly!